BIRD Energy Supports First-of-Its-Kind Pilot to Advance PVC Recycling in the U.S.

“This isn’t just about solving a waste problem - it’s about unlocking the potential of a valuable resource that’s been left behind,” said Tal Cohen, CEO and co-founder of Plastic Back. “With the right chemistry and the right partners, PVC can become a cornerstone of circular manufacturing”

A first-of-its-kind pilot project is set to launch in the U.S., aiming to enhance PVC recycling rates and showcase that PVC, long considered one of the most difficult plastics to recycle, can be efficiently transformed into valuable raw materials and reintegrated into industrial supply chains.

The project, to be commissioned in Q1 2026 at a Freepoint Eco-Systems’ facility in Hebron, Ohio, will test and scale a novel chemical recycling technology developed by Plastic Back. Supported by the Vinyl Institute and funded in part by the BIRD Energy program managed by the US-Israel BIRD Foundation, the pilot will process PVC-rich waste streams and serve as a collaborative platform, bringing together waste handlers, petrochemical companies, brand owners, and technology providers to demonstrate a scalable circular solution for PVC.

This pilot arrives at a critical moment, as regulators and industry stakeholders worldwide face mounting pressure to address plastic waste and accelerate circular solutions. In the U.S., Extended Producer Responsibility (EPR) programs and federal policy proposals are advancing mandates for increased recycling rates across all major plastic categories. At the same time, the vinyl industry has committed to ambitious circularity goals, including targets to grow post-consumer recycling of PVC to 160 million pounds by the end of 2025. Demonstrating that PVC can be chemically recycled at scale is essential for meeting both regulatory expectations and long-term voluntary ESG commitments across the value chain.

Plastic Back’s Breakthrough Technology

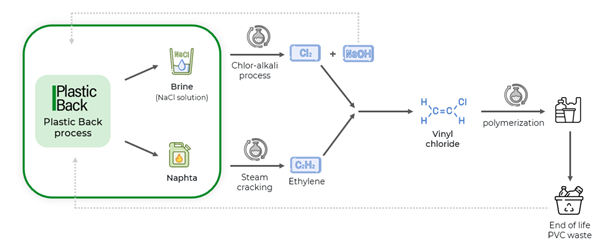

Plastic Back, the Israeli chemical recycling startup pioneering the transformation of plastic waste into valuable oil products, is expanding its presence in the U.S. through this landmark initiative. Building on research from the Hebrew University of Jerusalem, Plastic Back has developed a proprietary low-temperature chemical recycling process that safely dechlorinates and depolymerizes PVC.

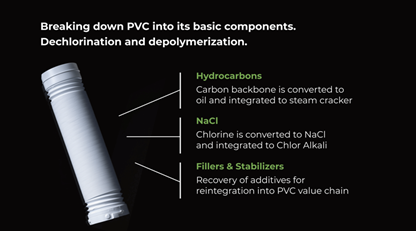

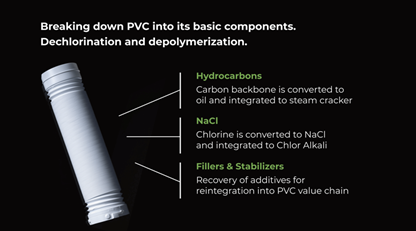

The result: high-quality oil-based feedstocks and mineral residues that can re-enter the chemical supply chain, without generating hazardous emissions or relying on energy-intensive processes. The Plastic Back process is uniquely capable of unlocking dual value from end-of-life PVC by:

• Dechlorination: Converting chlorine content into a purified sodium chloride (brine) solution, reusable in the chlor-alkali process, a core input for new PVC production.

• Depolymerization: Breaking down the carbon backbone into hydrocarbon oils, analogous to naphtha, suitable for use in steam crackers and refineries, creating direct value for the petrochemical sector.

Strategic Partnership with Freepoint Eco-Systems

Plastic Back is executing the pilot with Freepoint Eco-Systems, an affiliate of Freepoint Commodities. Freepoint Eco-Systems develops and operates state-of-the-art facilities that convert post-use plastics into usable products. The pilot will be hosted at Freepoint Eco-Systems’ large-scale plastic upcycling facility in Hebron, Ohio, which is capable of processing up to 90,000 tons of waste per year.

Their operational expertise, infrastructure scale, and market access make them a strategic partner in demonstrating how PVC waste can be industrially recycled and reintegrated into the materials economy.

“Freepoint Eco-Systems is using advanced recycling technology to help reduce the environmental impact of plastic,” said Jeff McMahon, Managing Director, Freepoint Eco-Systems. “Through a strong relationship with Plastic Back we look forward to creating a strong foundation for innovation to help address the global plastic waste crisis.”